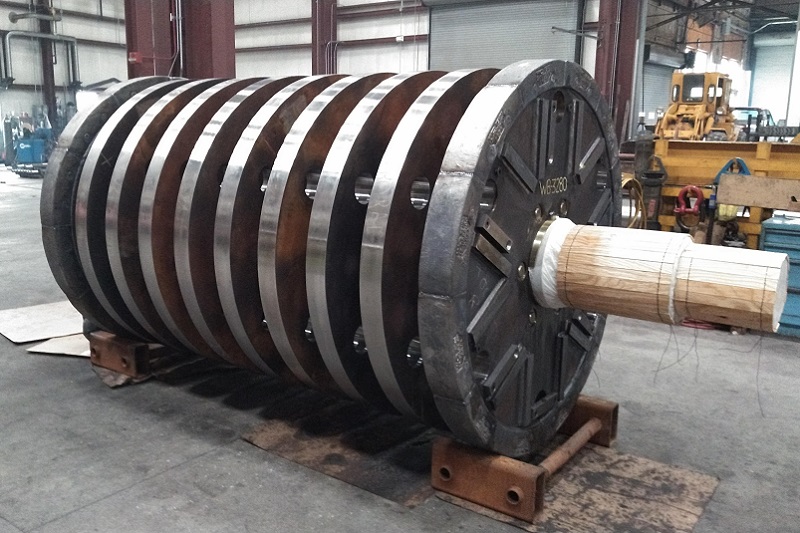

WENDT has an exclusive strategic partnership with the industry’s leading manufacturer of replacement rotors, Bowe Machine Company. Our complete line of DISC and Spider automobile shredder rotors are precision engineered for performance, increased durability, and a lower cost per shredded ton providing an unbeatable value. With 550 rotors installed worldwide, nearly 70% of the most productive shredder operators rely upon a WENDT/Bowe rotor for their success.

- Proprietary rotor design with close-tolerance machining and state-of-the-art assembly techniques.

- Finite Element Analysis (FEA) and computerized solid modeling are done to create a rotor design that is more robust.

- Rotor plate material is a specially developed alloy tool steel WENDT 360 material rolled, quench & tempered.

- Rotor shaft material ASE 4340 forged steel quenched and tempered to 277-321 Brinnell harness.

- Final Assembly of the rotor in Bowe’s new state of the art 32,000 sq. ft. rotor assembly facility allows us to ensure quality.