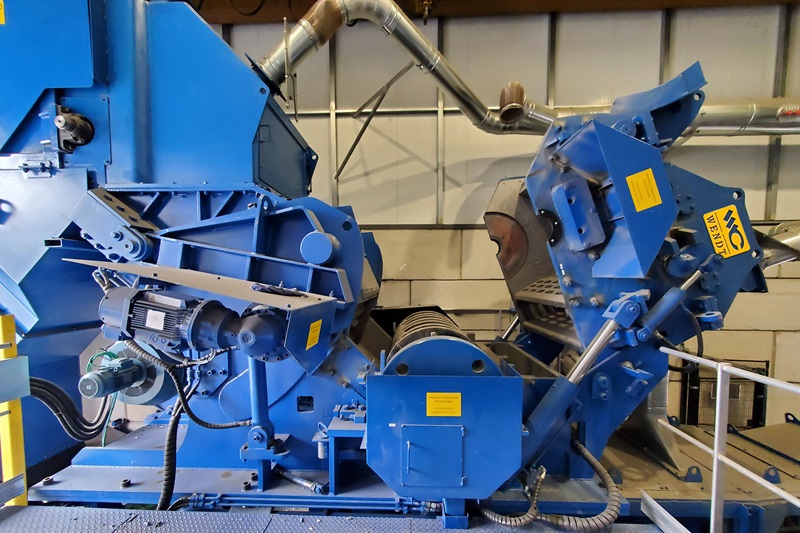

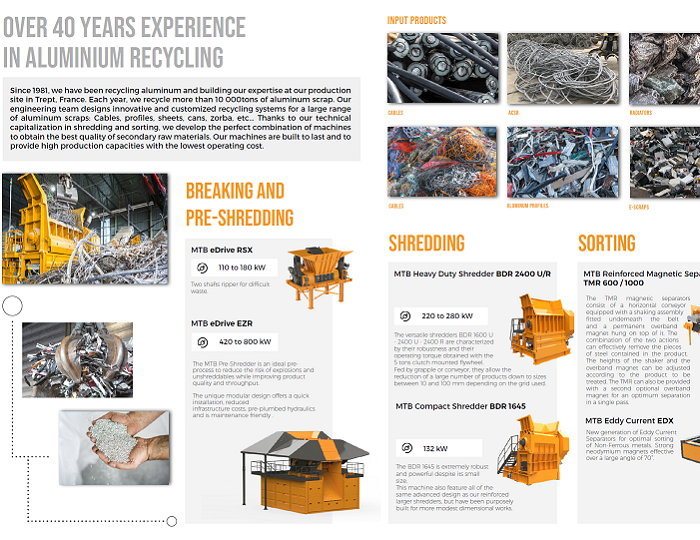

WENDT provides innovative systems designed and developed specifically for processing aluminum and non-ferrous material to create furnace-ready products. From taint/tabor to used beverage cans, zorba, breakage and aluminum extrusions, WENDT’s complete aluminum shredding systems are engineered to efficiently process various grades of aluminum to achieve exceptional recovery and value.

- Pre-Shredders

- Hammermill Shredders

- Knife Shredders