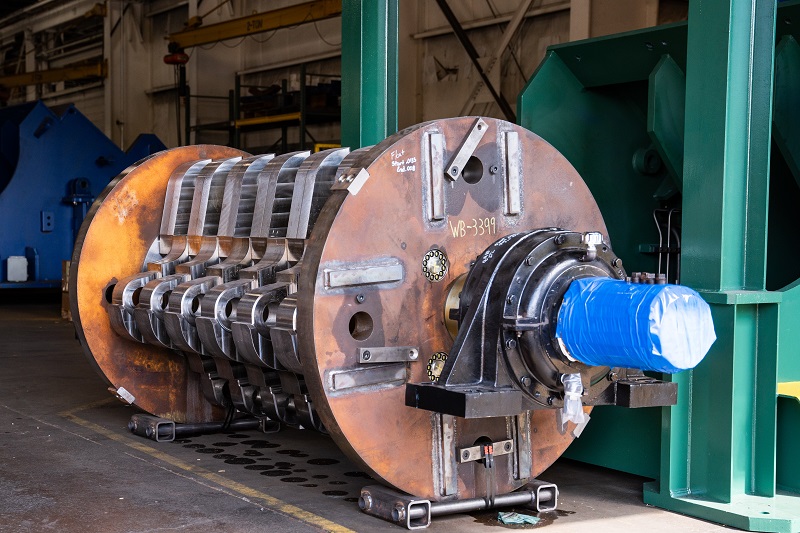

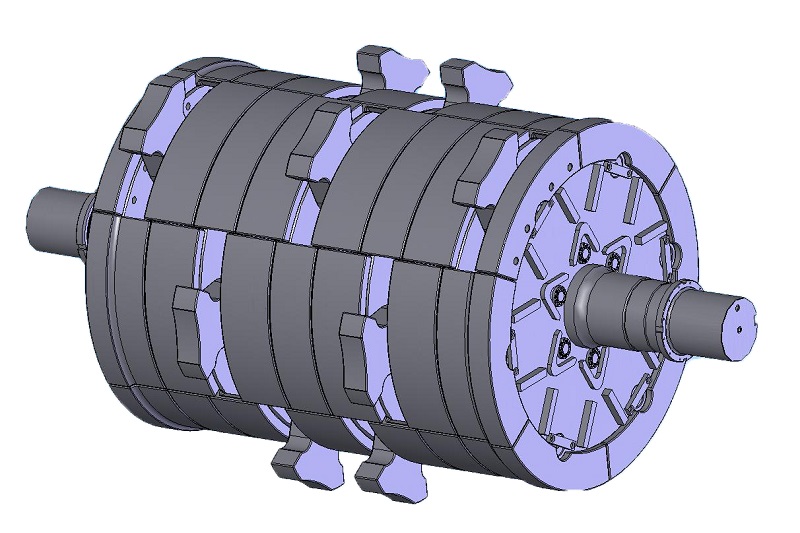

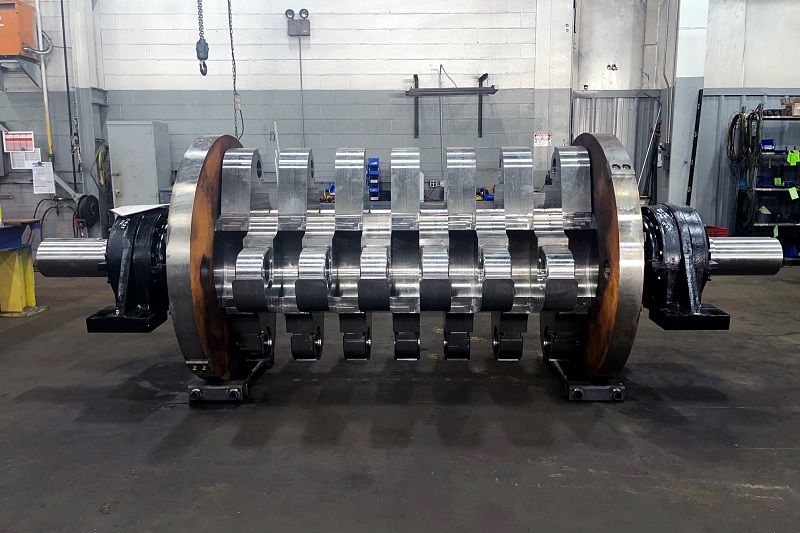

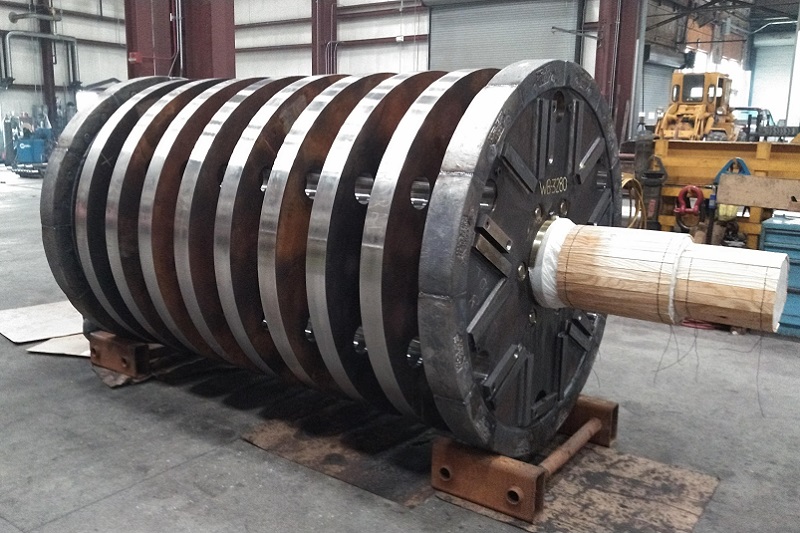

WENDT’s complete line of DISC, Spider, and Barrel automobile shredder rotors are precision engineered for performance, increased durability, and a lower cost per shredded ton providing an unbeatable value. With 550 rotors installed worldwide, nearly 70% of the most productive shredder operators rely upon a our rotor for their success.

- Proprietary rotor design with close-tolerance machining and state-of-the-art assembly techniques.

- Finite Element Analysis (FEA) and computerized solid modeling are done to create a rotor design that is more robust.

- Rotor plate material is a specially developed alloy tool steel WENDT 360 material rolled, quench & tempered.

- Rotor shaft material ASE 4340 forged steel quenched and tempered to 277-321 Brinnell harness.