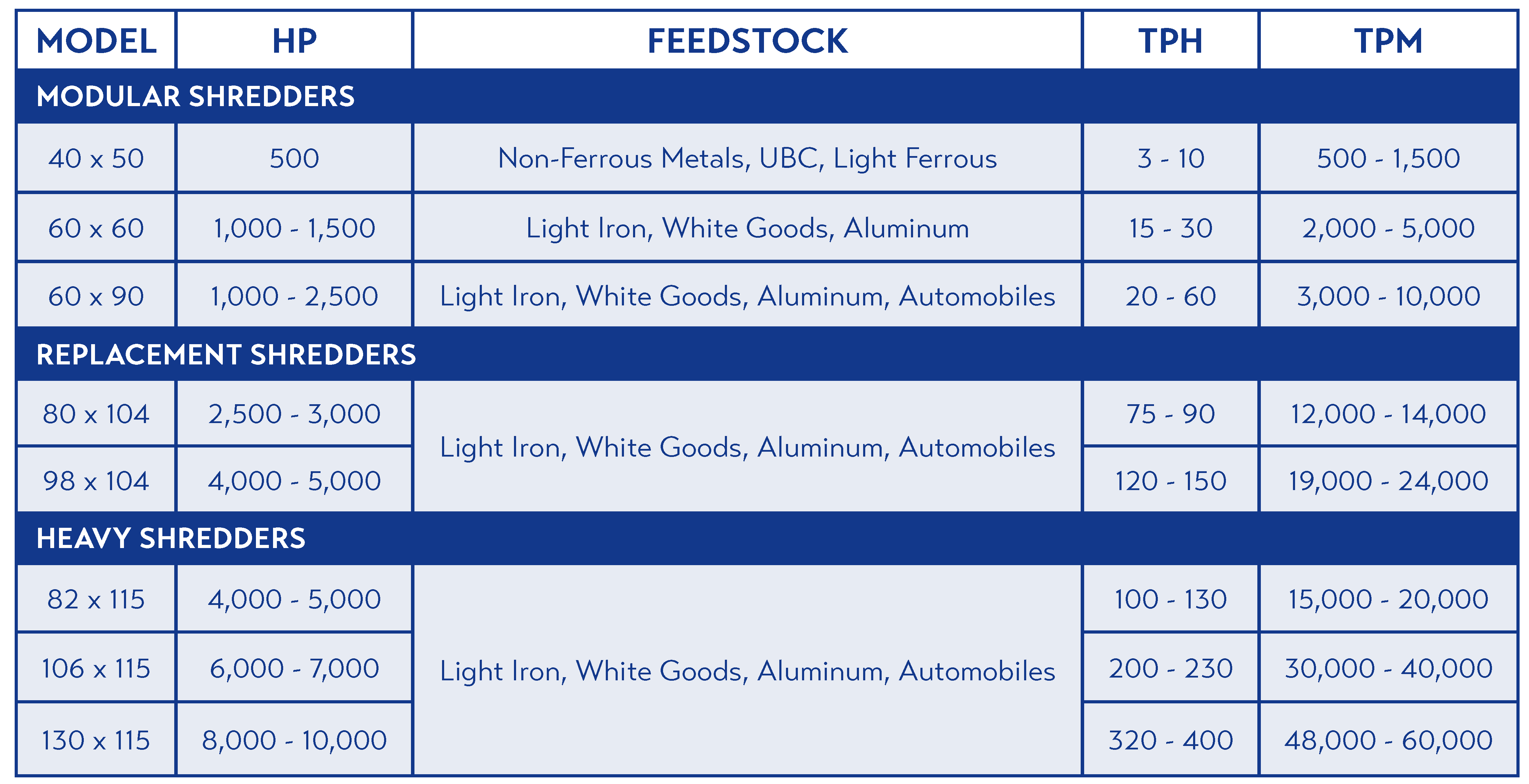

WENDT offers a comprehensive line of hammermill shredders capable of processing from 500 to 60,000 tons per month. From small, to mid-size to the largest shredder in the world, our over 45 years of extensive experience and know-how deliver the most innovative shredders in the scrap industry. All of our shredder designs are engineered to provide the highest production per kilowatt hour and lowest wear part consumption per shredded ton, while maximizing performance, reliability and safety.

Hammermill Shredders

Modular Shredders

Our modular shredders have a uniquely-engineered economical and efficient design that offers a small footprint and low cost of ownership. WENDT‘s Modular Features reduce installation cost duration, and total project cost when compared to traditional shredder installations with permanent infrastructure surrounding the shredder.

- Installs on a flat concrete slab, saving time and money

- Available turnkey with installation in less than 30 days

- Pre-Fabricated Steel Support Structure

- Pre-Fabricated Motor Building

- Electrical House (E-House)

- Fluid Power House

HEAVY Shredders

WENDT‘s hammermill shredders are designed to offer reduced energy consumption while producing clean, high-density scrap at optimum tonnages and the lowest cost per ton. With thicker steel and up to 50% heavier than other shredders on the market, the WENDT HEAVY shredder is designed to be the most durable, efficient, reliable, and serviceable metal shredder in the industry.

- Durability with heavy plate construction, reinforcing gussets and interlocking fabrication

- Efficiency with the highest production levels per kilowatt hour and lowest wear part consumption and cost per shredded ton

- Full box shredding and increased throughput, higher efficiency and greater product density with our advanced geometry design

- Reliability with robust construction and the most advanced design innovations to perform under the toughest shredding applications, maximizing up-time

Replacement Shredders

WENDT‘s 45+ years of experience allows us to customize our shredders to achieve maximum productivity in any footprint. Our line of replacement shredders allows us to upgrade old, outdated shredders with state-of-the-art technology and modular features that offer minimal downtime.

- Common sizes such as 80 x 104 and 98 x 104

- Interchangeable components with other standard-sized industry shredders

- Built with the same construction and design as our HEAVY™ shredder line

- Optimized geometry allows for increased throughput, higher efficiency, greater product density & lower costs

- Single or double feed roll assembly with hydraulic drive

- Modular features to allow for quick change out from old to new with minimal downtime

Features & Benefits

WENDT M6090 Shredding Plant

WENDT M6090 Shredder Plant Walkthrough with DMS Metals

WENDT Optimization