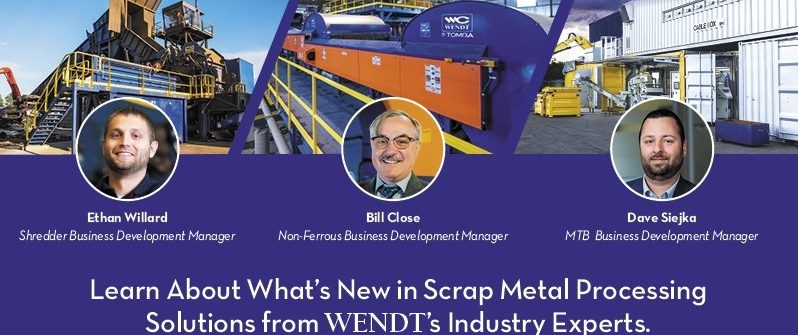

WENDT‘s Business Development Managers, Ethan Willard, Bill Close and Dave Siejka, sat down to discuss what’s new in scrap processing solutions. From new innovations and technologies to recent installations, our industry experts cover the latest and greatest in their individual product lines of shredding, non-ferrous separation and sorting and wire chopping.

Video Transcript:

Dave Siejka: Hi everybody and thanks for joining us today. Today, we’re going to be talking about what’s new in the industry, what’s new with some of our new WENDT products that we’re developing to help you guys with processing different grades of scrap material and we’re also going to talk a little bit about some of the new or the newer installations that we have either recently installed or in the process of being installed around North America. My name is Dave Siejka. I am the WENDT Business Development Manager for our MTB product line, which means I handle all of our chopping applications from wire to non-ferrous and radiators and a whole host of different types of materials. I’ve been at WENDT for about 13 years at this point. And I’ve worked in just about every department that we have here, so I’ve gotten the full tour of WENDT CORPORATION. I’m going to let my colleague introduce himself.

Bill Close: I am Bill Close. I am the Business Development Manager for the non-ferrous portfolio. So that’s where basically we’re dealing with the auto shredder residue and doing metal recovery and then metal sorting activities with the materials. I’ve been with WENDT for a little over 30 years and I’ve also had the full WENDT tour. I’ve had six different careers within the same company in that time. And my colleague here.

Ethan Willard: My name is Ethan Willard. I’m the Business Development Manager for WENDT‘s shredding and downstream product line, as well as our emission control systems for auto shredders. I’ve been at the company now for about 10 years. I started in the engineering department and have worked my way through engineering and project management and now sit next to these two guys on the business development side. I’m going to kind of get things kicked off here and talk a little bit about my product line, because of course mine is where everything starts and flows down to these two guys.

We’ve had some really exciting things happen this year, both on the technology side and the installation side, a lot of firsts for us and a lot of really cool projects and new things for us. The first big one is the EZR Pre-Shredder that we are promoting with our partners, MTB. The Pre-Shredder last year we started talking about it and this year I can proudly say we have two of them now in operation and are really looking forward to a few more here in this coming year to really kick off the whole product line. The Pre-Shredder allows us to bring our customers to the next level when it comes to shredding and separation. It allows them to increase their throughput on their shredders. It allows them to reduce their operating costs and improve their sorting efficiencies. We’re really excited for that, especially for our shredders, our customers who have shredders installed for many, many years. This is kind of the next step for them to be able to expand their business and grow their business.

The other big one for us is our 6090 product line. So, as many of you probably know, WENDT is known for our modular shredders. We deliver 6060 and 6090 sized shredders that are fully containerized. The controls come into a container, the hydraulics come in a container, and they all sit on a flat slab on your site for quick and easy installation, limiting your infrastructure, and your overall project costs. Up until recently though those modular features were only available with one motor and this year we’re actually releasing a next generation of the machine that gives us a lot more flexibility on motor selection and allows us to offer multiple different motor types for the same machine. So again, that’s another really exciting thing for us from a technology standpoint.

We also had a couple of really cool installations. One of the biggest ones is a brand new 130-inch, 8,000 horsepower shredder that we installed complete with everything from the shredder to the ferrous downstream and a very large non-ferrous separation plant. As well as a first of its kind of emission control system for the industry. This was a brand new greenfield site, where WENDT delivered everything from the infeed conveyor to the finished products on the non-ferrous plant and of course the emission control system. So that, that was really exciting for us this year.

Then on the smaller side, we delivered a brand new 6090 plant, just North of us here in Ontario, Canada. That is for a brand new shredder operator. They were a scrapyard for many, many years, family-owned, and now they decided to take the next step into the shredding world and invested with us on the 6090 with a ferrous downstream and a small non-ferrous plant. That plant is a beautiful installation. It’s nice and close to us here in Buffalo, so it’s a great plant for us to take our customers to and visit here once COVID starts to slow down. It’s been a really exciting year for us and we’re looking forward to this upcoming year and continuing to work together on delivering complete solutions from the infeed conveyor to the shredder to finished products. I’m gonna pass it over to Bill now and talk a little bit about this product line.

Bill Close: I always jokingly say to Ethan that the non-ferrous is just picking up where the shredder takes off and the shredder is nothing more than an ASR preparation tool. Where we go from there basically is a first step would be a metal recovery plant. WENDT has had a leadership position in the marketplace for non-ferrous recovery plants for going on 15, 20 years right now. We’ve got a very significant market share on that. In the last recent period, we’ve had multiple installations going into Canada, ranging from 20 ton an hour, 35 ton an hour facilities. We’ve got a couple, sales booked that are smaller up in Canada that will shortly be delivered. In the United States, on the West coast, we had a nice 35-ton an hour plant that was recently commissioned. We have a video about that, I’d be happy to share with you guys. There’s been a lot happening within the metal recovery sector.

The what’s the new portion, I would say, one of the more interesting things would be a fines process that could be added on to any existing plant or incorporated as part of the new build. This, in addition to being a Zorba recovery, we’re extending that process with some very simple methods of concentration, maintaining a dry process, and featuring the TOMRA sensor-based sorting with FINDERS. With that, we’re able to in one pass make a copper concentrate that when chopped on an MTB system would be greater than 60% recovery of copper. That’s the fines portion.

Next I would like to talk about what we’re doing with metal sorting. TOMRA has introduced the fines version of the XRT. So now we can process down to a five millimeter Zorba as input, and as you know, the Zorba fines is where you have the highest concentration of your red metals, and it’s your highest revenue generating opportunity. This is an enhancement that has been offered for the XRT’s that will allow you to get down to a five millimeter particle size. In addition to that, we have a new partnership to announce with DIDION and our metal polishing drums. When we’re taking Zorba coming off the metal recovery plant, it goes through the metal polishing drum, basically it’s an agitation of metal on metal with some air de-dusting and some screening. The purpose of this basically is to produce a polished metal product to meet the ever-increasing demands of our industry for product purity. The metal and metal action basically scrubs off all the surface contamination off the product, as well as some of the oxidation, producing a really nice package that can be exported. We offer an export version of that drum that will also do the screening requirements, so that we can produce a pre-sized, polished, Zorba package ready for export to China. This same drum technology has an opportunity to be integrated with metal sorting with the XRT, where this is going to be a significant advantage, particularly in the color sorting aspect. Your polished, bright, shiny copper, brass, highly visible to color based systems, which will increase the recovery of the red metals. So there’s a lot of new things that we’re talking about and have implemented. I’d be very happy to set up some tours to show you these different materials. So part of the recovery plant is producing a wire package, which is ready for the MTB portfolio.

Dave Siejka: Thanks Bill. One of the things that I like to remind these guys about is that where they’re dealing in cents per pound for their outputs, I’m dealing in dollars per pound for mine, so my process is creating the most value. No, but while we’re talking about commodities, kind of one of the cool things that we’re seeing going on right now over the past couple of years has been an increase in metal commodity prices. I mean, copper is skyrocketing. Aluminum is coming along. Those markets are also just going to continue to get hotter with everything that we’re seeing from a push towards sustainability. Whether it be electric vehicles or infrastructure, or a whole host of different reasons why those metals are becoming a little bit more valuable. On the ferrous side I’m not as well versed, so Ethan, are we seeing the same thing over there?

Ethan Willard: Ferrous is definitely the same from this time last year. Ferrous is obviously been up quite a bit and we’re looking forward to a good year this year as well.

Dave Siejka: I mean that’s obviously that’s good for us for equipment sales, but that’s also very good, obviously for our customers, the people that are running our equipment. One of the things that we’ve been doing with our MTB product line is developing new machines and improving processes and creating processes that are going to help our customer base to really extract that value out of the material. Starting with the EZR that you kind of brought up earlier Ethan, at MTB we have a full scale plant that starts with our EZR and includes another MTB shredder on it and then also includes X-TRACT on the back end, it includes some Eddy Currents, it’s a whole process. This process is geared towards taking different aluminum grades, whether it be Taint Tabor, whether it be Extrusion, aluminum siding, radiators, a whole host of different aluminum products, taking it, shredding it, sizing reducing it, and then turning it into very clean sellable aluminum, and heavy reds material.

We also have developed a vertical mill. This vertical mill can be a pre-process for anything ranging from dirty ASR wire to small motors, meatballs, irony aluminum, a whole bunch of different types of materials, which once liberated and we go through a WENDT process to remove stainless steel, remove steel, remove aluminum, what’s left is lights, and then those lights can go to a wire chopping line. We’re taking those materials and we’re upgrading everything into clean sellable commodities.

We also have a RDF Shredder that’s come out, that’s designed towards helping shred different waste materials and tires and things of that nature. The traditional MTB shredder for our wire chopping lines, the BDR, we’ve developed a hydraulic pusher for that. It’s available as a retro kit that can be added on to any of our BDR’s out in the field or it can be ordered new from the plant. What that’s going to help you do is with some of the lighter types of materials, it’s just going to help you boost your throughput a little bit and make sure that we’re forcing that material into the shredding chamber where we’re getting our size reduction and our liberation.

We’ve also taken our our standard CABLEBOX, which is a downsized version and a containerized version of a full-scale wire chopping line we’ve taken that CABLEBOX and we’ve reduced it to a CABLEBOX ONE, which is one container. It’s got a whole bunch of value packed into it from the installation point. All the sunk costs associated with a wire chopping line installation are built into those box. So there’s a lot of value in there and it’s basically just a smaller version of our CABLEBOX. It’s geared towards, maybe single shredder operators producing lower volumes of ASR wire or some of the smaller, lower volumes of materials out there.

In addition to a lot of the new stuff that we’ve been developing, we got a whole host of installations going on top. Our installation crews are out there very busy on the MTB side. We’ve got some new CABLEBOX’s in Canada and North America. We’ve got a couple of CABLEBOX ONE’s that have been installed over the past year. We’ve got a full-scale line down in Mexico, a couple of big lines up here in North America as well, and the States as well. We’ve just been really busy on the installation side. And one of the kind of cooler installations is actually up in Canada. It’s a CABLEBOX ONE that has been installed at this site and this CABLEBOX ONE is processing almost exclusively ASR wire. It’s an interesting story because it really started on Ethan’s side of the business. How many years ago Ethan?

Ethan Willard: It was about four or five years ago. This customer runs a competitor shredder to our product line and they reached out to us asking for help. They wanted to convert the machine from a Spider to a Disc Rotor. We went in there and we converted the machine over, increased their throughput, increased their uptime and helped them out in any way that we could. The upgrades to the shredder were a great success and they’ve continued to work with us over the years and within a year or so of making upgrades to the shredder, they reached out to Bill on the non-ferrous side as well.

Bill Close: After those upgrades and operational efficiencies, the non-ferrous recovery plant was then generating products that came back to what Dave was talking about with the CABLEBOX ONE. We work as a team approach here. We have a very diverse group of people within our organization, lots of different skill sets. In addition to the experience that’s sitting here at the table talking about processes and applications, behind us and supporting us is a large engineering team, project management team, a customer service team, and field service reps as well. I’d encourage you to check out some of our videos on the website. We’ve got some great videos, customer testimonials from the shredder side, from the non-ferrous, and also from the MTB side. Our customers tell our story far better than we do, and I really encourage you to check that content out.

Dave Siejka: I think Bill a lot of what you’re kind of saying there with the infrastructure on the backend is really what’s helped us to develop many customers like the one that we just talked about, where we’re doing multiple projects, because we’re bringing value at each stage of the recycling project. I think one of the videos that we have on our website right now, and Ethan, you can talk a little more to that, the 6090 customer up in Canada.

Ethan Willard: The new 6090 that I mentioned earlier in the video, that’s a customer, who, like I said, it was a greenfield site a year ago when they commissioned the shredder. It was at the time, a simple 6090 shredder with a very simple ferrous downstream and two-line eddy current plant. What we had done is, that we knew this customer had an appetite to be able to grow and expand their business and so we designed the plant from the get-go to be able to expand and grow as their business grew. Lo and behold, a year later, they’re already looking to expand the non-ferrous side. They started off with a shredder generating a few different types of shred packages with a 6090 and then just the simple, Zorba process for recovering Zorba and essentially focusing on the high revenue streams, the easy to get material. Then just not too long ago, they reached out looking to add FINDERS.

Bill Close: We’re expanding what was a two eddy current plant producing just Zorba to it’s now a three eddy current plant. We’ll have a more efficient recovery of additional Zorba and follow it with sensor-based sorting with TOMRA FINDERS doing Zurik and a wire package coming off the line generating additional revenue. That very nicely will present the opportunity for a great future where they can expand once again and use the MTB portfolio to convert that wire package into a high value furnace-ready copper.

Dave Siejka: I mean it’s the way we kind of work, it really speaks to our one partnership philosophy, whether it be shredding or non-ferrous or wire chopping, any of the partners that we work with, we always work with our best-in-class partners and they’re part of our organization. We want to develop one partnership, we want to be one partner with you. Our customer’s success is the greatest thing we can do as an organization, and it’s just to bring success to our customers. That’s really what we strive to do. From our first conversation through 10 years down the line when you’ve been running your equipment and you’re looking for parts. We strive to bring value to our customers and help them succeed through that whole process. I think that’s really what makes us special is we don’t just say that, we’ve got the infrastructure to do that with our backend in our building. Do we have anything else that we want to talk about or do we want to let these guys go?

Ethan Willard: I think we’ve been talking long enough. I think we should probably let them go. Thank you guys all for joining us and watching the video. Please take some time and browse through some of the new videos where we’re posting. I think you’ll see a lot of cool content there and hopefully spark a few ideas. As always feel free to reach out to any of us here at WENDT. You can find our contact information on our website and we look forward to hearing from you soon. Thanks for watching.

Comments are closed.